We have explored technologies that are hard and precise, from the atomic scale of nanotech to the rigid structures of traditional industrial robots. Now, let’s consider a unique and revolutionary frontier that is turning robotics on its head. This is the realm of soft robotics, a field that is creating robots from highly compliant and deformable materials, such as silicone and rubber. Instead of being built for strength and speed, these machines are designed for safety, adaptability, and the ability to interact with the world in a more fluid, organic way.

This article will explore the unique nature of soft robotics, what makes them a fundamental departure from their rigid counterparts, and their potential to unlock new applications in medicine, manufacturing, and exploration.

What Makes a Soft Robot Unique?

A traditional robot, like those found in an automobile factory, is built from rigid materials and relies on complex software and sensors to perform tasks with a high degree of precision. Soft robots, on the other hand, derive their intelligence and functionality from their physical bodies and materials. Their unique nature is defined by three core principles:

- Physical Compliance: The most obvious difference is the material. Soft robots are made from flexible materials that can bend, stretch, and deform without breaking. This allows them to absorb energy on impact, making them inherently safer for direct human interaction.

- Infinite Degrees of Freedom: Unlike a rigid robot with a fixed number of joints, a soft robot has an infinite number of possible movements, which allows it to squeeze into tight spaces, conform to irregularly shaped objects, and perform complex manipulations that are impossible for a rigid machine.

- Body as the Controller: In many cases, the intelligence of a soft robot is encoded directly into its physical design, not just its code. For example, a robot’s shape can be designed to perform a specific task when a fluid is pumped into it, requiring minimal sensor feedback or complex algorithms.

Their unique method of movement, known as actuation, also differs from traditional robots. Soft robots are often powered by pneumatic or hydraulic systems, where pressurized air or fluid is used to inflate internal channels, causing the robot to bend, grip, or crawl.

The Revolutionary Applications of Compliant Machines

The ability to create robots that are gentle, adaptable, and flexible has the potential to solve some of the most difficult challenges in robotics today.

1. A New Era of Human-Robot Collaboration

The safety of soft robots makes them ideal for working alongside humans in shared environments.

- Surgical and Medical Devices: Soft robots can be used for minimally invasive surgery, navigating the body’s delicate tissues without causing damage. They can also be used in rehabilitation to provide gentle, adaptive support for patients recovering from injuries.

- Assisted Living: Soft robotic exosuits can assist the elderly or people with disabilities by providing a gentle boost to their natural movements, helping them to walk or lift objects without the risk of injury from a rigid, motorized frame.

- Gentle Grippers: The ability of soft robots to conform to the shape of an object makes them perfect for handling delicate items, like fragile fruits in an agricultural setting or glassware in a manufacturing line, without causing any damage.

2. Exploration in Unstructured Environments

Rigid robots are great for structured environments like factories, but they struggle in unpredictable ones. Soft robots excel in these chaotic settings.

- Search and Rescue: Soft robots can be designed to squeeze through cracks and rubble in collapsed buildings, navigating confined spaces to search for survivors.

- Deep-Sea and Space Exploration: Their ability to withstand extreme pressures and conform to irregular surfaces makes them ideal for exploring the ocean floor or the surface of distant planets, interacting with delicate ecosystems or scientific samples without causing harm.

The Challenges and the Path Forward

While the promise is immense, soft robotics is still in its early stages. The field faces several key challenges:

- Complex Modeling and Control: The very thing that makes soft robots so adaptable—their infinite degrees of-freedom—also makes them incredibly difficult to model and control with precision.

- Durability and Longevity: The flexible materials used in soft robots are susceptible to wear and tear, and developing materials that can withstand thousands of cycles of deformation is a major engineering challenge.

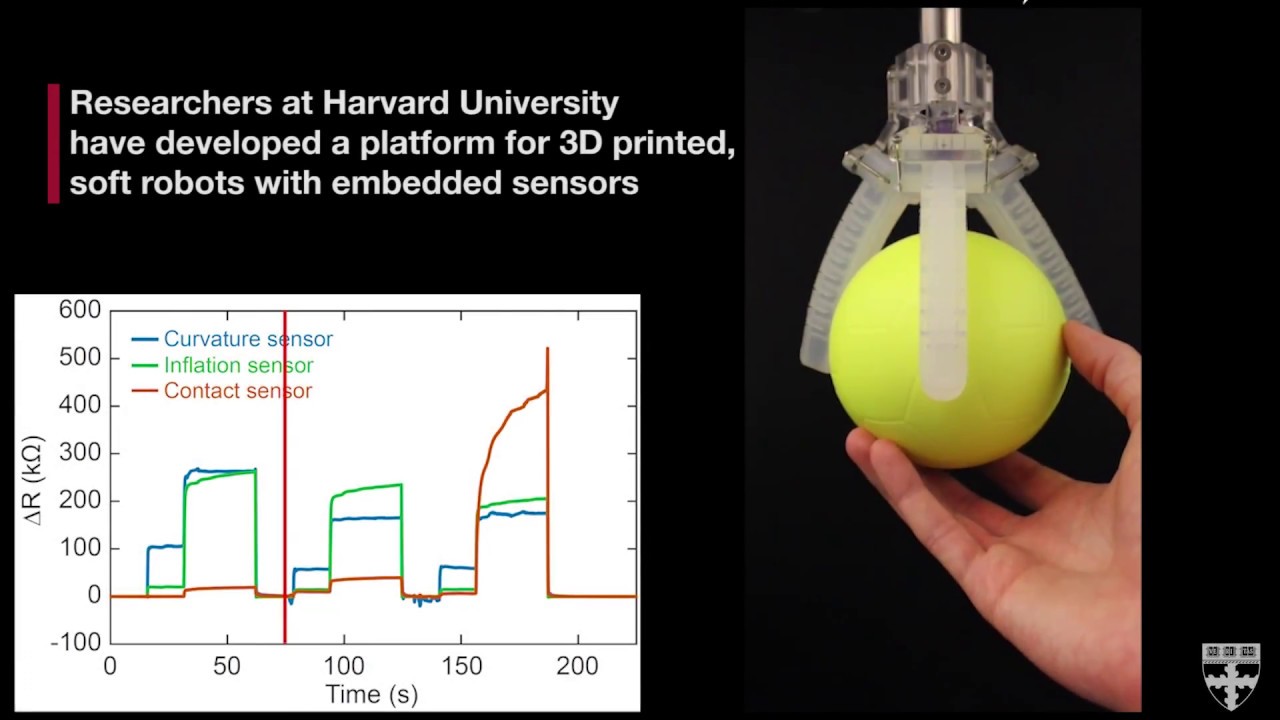

- Integrated Sensing: To be truly autonomous, soft robots need to be able to “feel” their environment. Developing soft, flexible sensors that can be seamlessly integrated into the robot’s body without compromising its compliance is a key area of research.

In conclusion, soft robotics is a unique and transformative field that is moving beyond the traditional image of a rigid, metallic robot. By embracing the principles of biology and the elegance of compliance, we are creating a new generation of machines that are safer, more adaptable, and more capable of working in partnership with humans and the natural world.

The following video shows how Harvard engineers have given soft robots a sense of touch. How Harvard Engineers Gave Soft Robots the Sense of Touch.

How Harvard Engineers Gave Soft Robots the Sense of Touch – YouTube

Harvard John A. Paulson School of Engineering and Applied Sciences · 10K views